Choosing the right coatings dispensing machinery can help lower investment costs and reduce project planning times for automotive suppliers.

Choosing the right coatings dispensing machinery can help lower investment costs and reduce project planning times for automotive suppliers.

The potting process is one of the most complicated steps in the production of automotive ignition coils. Since it can also be the most expensive, many automotive suppliers are hesitant to implement complex machinery. However, an alternative to expensive custom-built systems has been developed that provides an economic solution for small- to medium-sized automotive suppliers. The proven vacuum dispensing system* consists of a standardized set of modules that can be combined into a repeat accurate vacuum production system. The system can be sized to suit any budget, and equipment modules can be customized for ignition coil production. The production line modules are manufactured in volume production, offering an advantage over custom systems.

The Ideal Process

Every driver wants a dependable vehicle whose engine starts in any weather and climate-whether it's -20°F on ice and snow or 110°F on sandy, windy roads. The automotive industry strives to meet these stringent quality standards, and ignition coil manufacturers must subsequently meet or exceed these standards as well. Even the tiniest inhomogeneity, bubble or cavity can result in a reject during production or failure in the field.

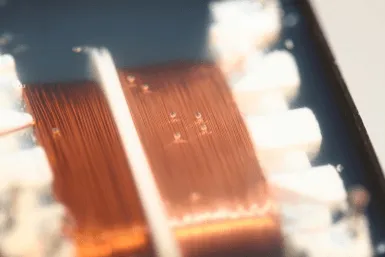

To guarantee maximum operability of an ignition coil, dispensing must be done in a vacuum. First, however, the process ideally starts with the proper preparation of the dispensing material. In many of today's applications, adhesives, sealants and potting materials with high-precision properties are coming onto the market. These media place high demands on their preparation and delivery. No compromises should be made here, because only with the aid of a homogeneous and bubble-free material can optimum dosing results and thus a high component quality be ensured. Custom-built stirring mechanisms, tank degassing and material feed lines, pumps, and airtight sealed valves are the initial minimum requirements. Scheugenpflug has suitable processing and conveying units in its range especially for vacuum applications. These have processes such as homogenizing, tempering, circulating and evacuating with which the processing properties of the medium can be specifically influenced and adapted to the dispensing task. Airtight dispensers and a parametrized vacuum control then round off the vacuum process.

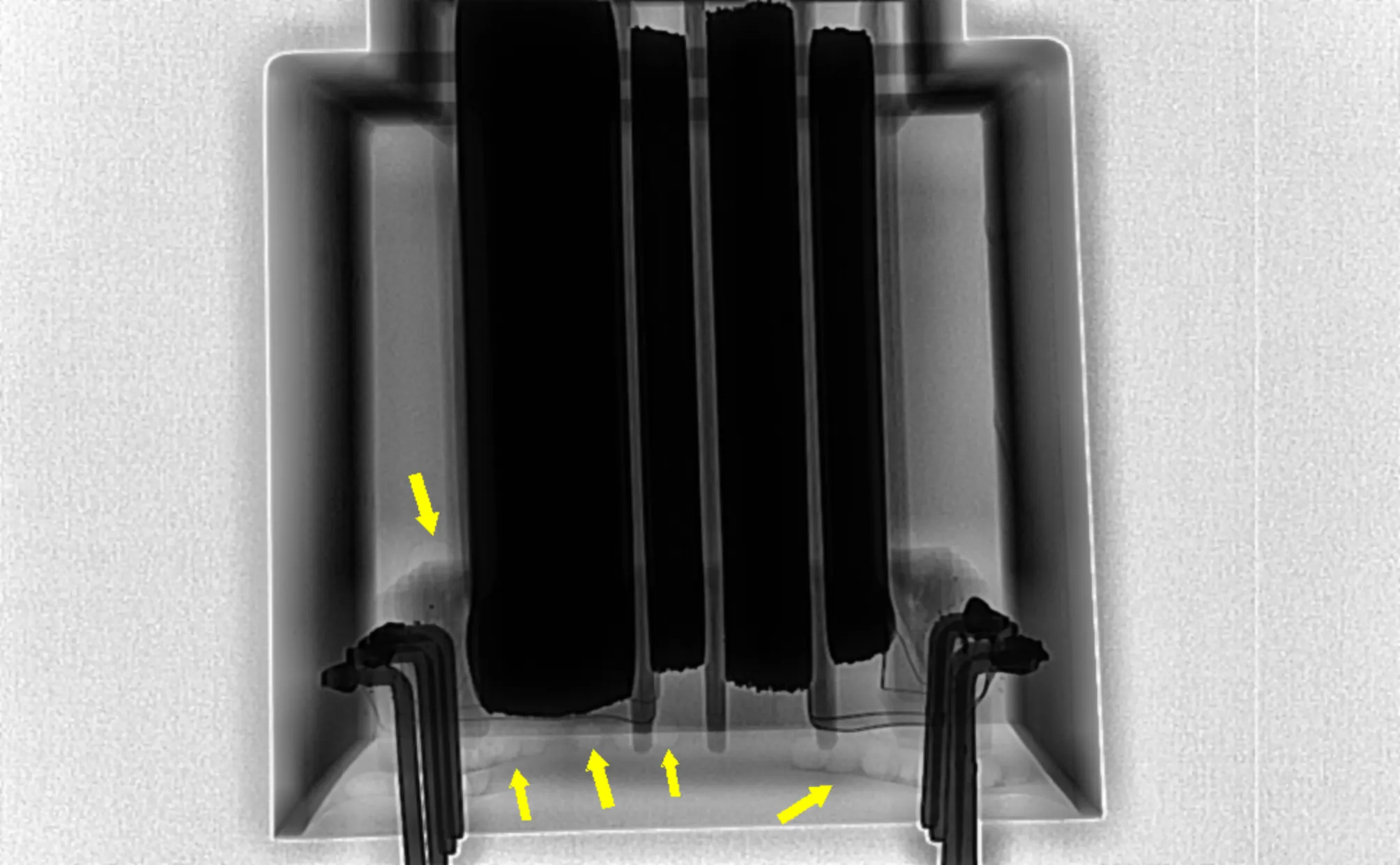

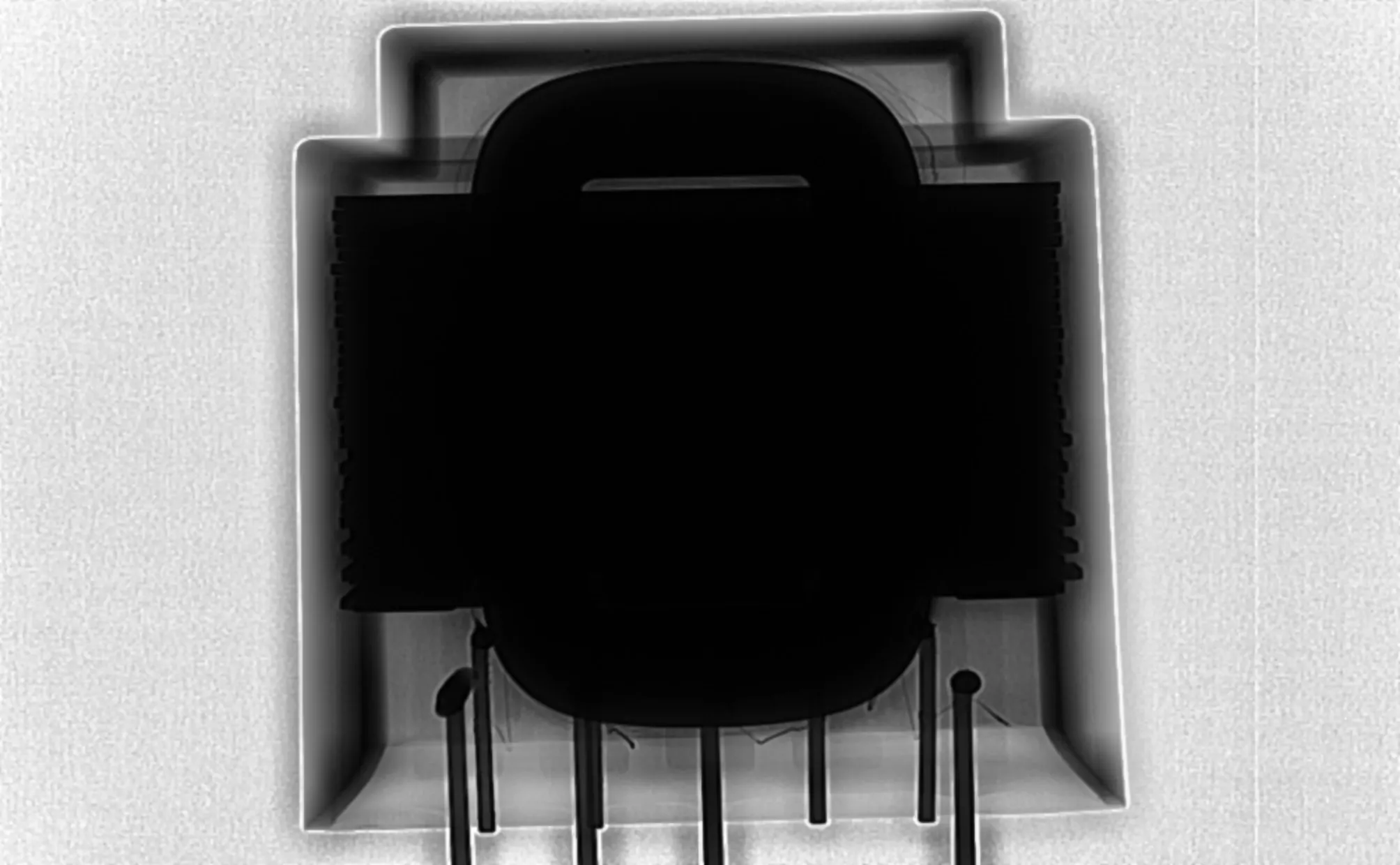

Most dispensing materials for potting ignition coils contain jagged fillers for better heat dissipation. Unlike conventional machines that experience increased wear and tear, which raises costs for spare parts, Scheugenpflug vacuum impregnation and encapsulation processes help protect the electromagnetic coils from corrosion and improve their electrical and mechanical properties. When potting ignition coils, it is essential to remove all air from the delicate coils of the component. Air pressure is lowered to about one millibar or less (absolute pressure) during the dispensing process to remove even the tiniest air bubbles deep inside the coiled section of the part. This is a much lower pressure than in conventional vacuum applications. Already during the filling process under vacuum, the dispensed material penetrates far into the fine gaps of the component. During the subsequent pressure build-up, the medium is then pressed into even the finest gaps and cavities.

Standard System, Modular Design

Production vacuum modules are optimized for ignition coil encapsulation, including material preparation units and vacuum chambers equipped with more efficient pumps, and double-walled hoses and lines (with a vacuum between the two tube walls) that prevent air from diffusing into the dispensing material through the hose wall. Using these affordable accessories, every standard vacuum chamber becomes suitable for fine and high-vacuum applications, including filling ignition coils.

This modular plant design concept, which has been implemented by many automotive suppliers, uses standardized modules that can be flexibly combined with one another. Due to their universal interfaces, these modules can be easily adapted to requirements and retrofitted/converted to newly emerging production requirements.

Intuitive controls require little operator training, saving the company education and familiarization costs. lt is an overall economic system that delivers accurate output and superior process reliability, in both its semi-automated and fully automated versions.

Finding the Best Solution

lt is recommended that companies consult a vacuum dispensing specialist beginning at the planning stage of the system and onward. Many details-such as the design and shape of the substrate, upstream and downstream production processes, curing, and more-have considerable impact on the dispensing process. Therefore, professional analysis, combined with mature processing technology and the correct choice of machinery, can considerably lower investment costs and reduce project planning times.

* Available from Scheugenpflug Inc., a subsidiary of Scheugenpflug AG

(1)

(1) Small traces of air appear in the fine gaps of the coil. This is the reason why it is advisable to pot wound materials under vacuum.

(2a) (2b)

(2a) Component potted under atmospheric conditions shows entrapped air

(2b) Component potted correctly under vacuum without air pockets

Contact

Scheugenpflug Inc.

Phone: 1 770 218 0835

Email: [email protected]

About Scheugenpflug:

The Scheugenpflug AG (Neustadt/Donau) is a leading manufacturer of precision engineered systems and machines for efficient adhesive bonding, dispensing and potting processes. The product and technology range extends from cutting-edge material preparation and feeding units and high performance manual work stations to modular in-line and automation solutions, specially tailored to customer specifications. Scheugenpflug systems are used in the automotive and electronics industries as well as the telecommunications sector, medical technology and the chemical industry. The company has four additional locations in the USA, China and Mexico as well as numerous service locations and sales partners all over the world. Due to its considerable expansion Scheugenpflug was able to double its number of employees within 5 years and now employs more than 500 staff.

For additional information go to www.scheugenpflug-dispensing.com